If you have a well water system, your pressure tank plays a critical role in making sure water flows smoothly and consistently to your home. While it often sits out of sight in a basement or utility closet, the pressure tank is working 24/7 to regulate water pressure, protect your pump, and keep your plumbing running efficiently.

Below, the pros here at Sperry Drilling Inc. explain how pressure tanks work, the components inside them, and why having the right tank – and maintaining it – is essential for a reliable well water system.

What Is a Pressure Tank?

A pressure tank stores water under pressure, using compressed air to maintain water flow and reduce wear on your pump. It works as part of a closed-loop system with your submersible well pump, ensuring your home always has water ready when needed – without the pump having to run every time you open a tap.

Think of the pressure tank as a shock absorber in your water system. Instead of your pump cycling on and off repeatedly, the tank holds water and releases it as needed, extending the pump’s lifespan and maintaining stable pressure.

Key Components of a Pressure Tank

A typical pressure tank has three main internal elements:

- Water Chamber: The portion of the tank that fills with water from your well.

- Air Chamber or Bladder: Contains compressed air that pushes against the water as it fills the tank.

- Pressure Switch: Monitors pressure levels and tells the pump when to turn on and off (e.g., 30/50 or 40/60 PSI settings).

There are two primary types of tanks:

- Bladder or Diaphragm Tanks – Use a flexible membrane to separate air and water. These are most common and reduce air absorption issues.

- Air-Over-Water Tanks – Older style tanks where water and air are in direct contact. These require more maintenance to maintain proper pressure.

How Pressure Tanks Stabilize Your Water System

Here’s how the system works:

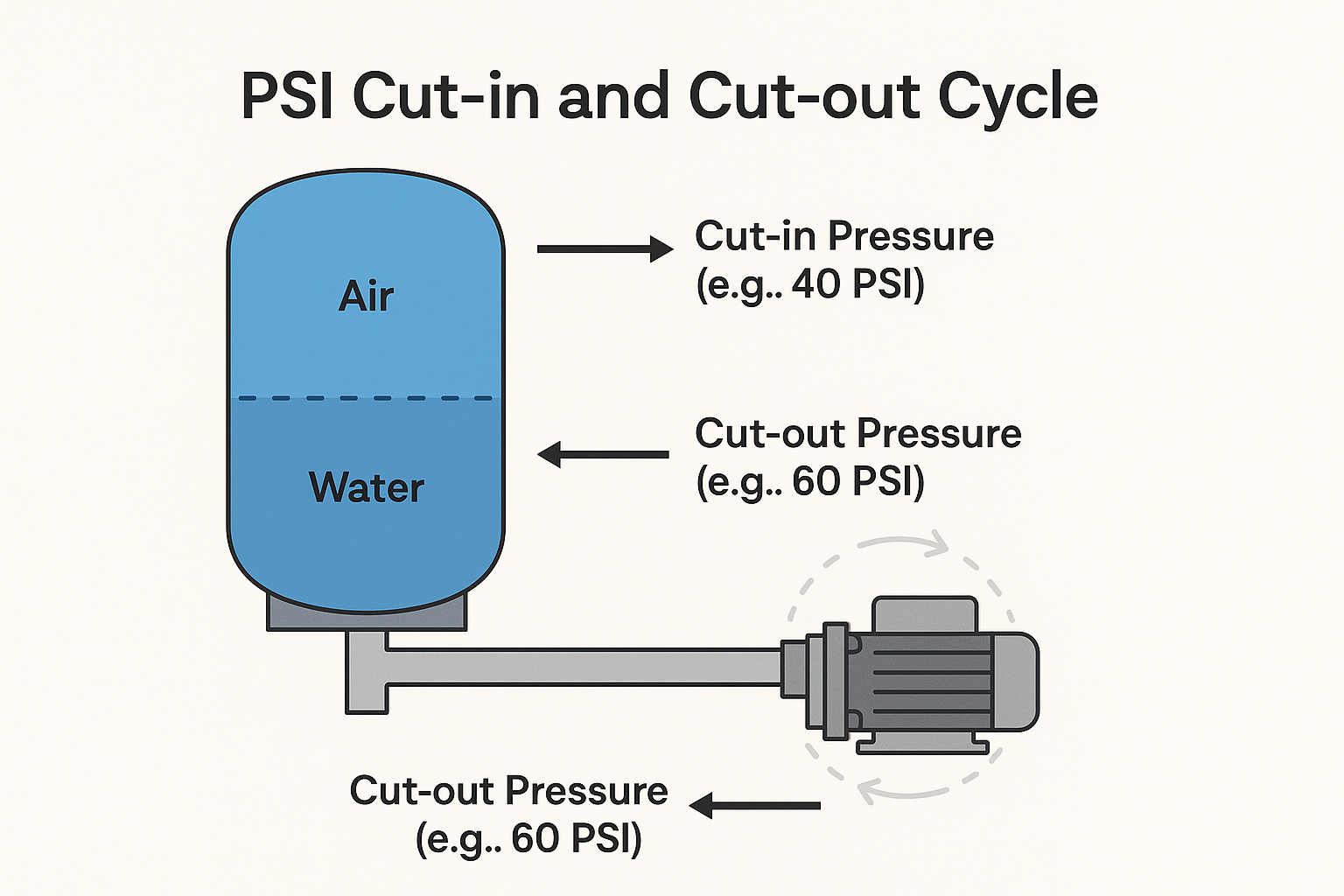

- Your pump fills the tank until it reaches the cut-off pressure (e.g., 50 or 60 PSI).

- As you use water, pressure drops in the tank.

- When the pressure reaches the cut-in level (e.g., 30 or 40 PSI), the pressure switch activates the pump.

- The pump refills the tank and the cycle begins again.

This cycle keeps your water pressure consistent and prevents short-cycling—a condition where the pump turns on and off too frequently, which can lead to motor burnout.

Why Pressure Tanks Matter for Your Well System

Here are four key reasons why your pressure tank matters:

- Extends Pump Life: Reduces frequent starts and stops, lowering wear on your pump.

- Consistent Water Pressure: Prevents pressure surges and fluctuations in showers, faucets, and appliances.

- Protects Plumbing: Limits water hammer and stress on pipes and valves.

- System Efficiency: Helps your entire well system run more smoothly and reliably.

If your water pressure is inconsistent, or your pump is cycling too often, it might be time to inspect or replace your pressure tank.

Ensure Reliable Water Pressure with the Right Tank System

At Sperry Drilling Inc., we professionally install and service a range of high-quality water storage tanks designed to meet the unique needs of residential and agricultural well systems. Whether you need a fiberglass filament tank for corrosion resistance or an epoxy-coated steel tank for high-pressure performance, we offer custom sizing, AirCell technology to prevent waterlogging, and durable construction for long-term reliability.

Call (814) 267-3487 or contact us online to schedule a system evaluation or pressure tank replacement.